Thanks to HVES, the percentage of high quality beef increases

(up to 50% of meat is sold at a higher price).

Rapid pH decrease

Six hours after slaughter, stimulated half carcasses reach about 5.7-5.9 pH which allows the processor to:

- apply fast and ultra fast cooling methods directly after slaughter with no risk of cold shortening,

- sell the carcasses to other meat plants or cool them exactly on the slaughter day.

Reduced time needed for aging

From 14 days to 24 hours.

Improved tenderness by 40%

24 hours after utilizing HVES technology the stimulated half carcass shows more tenderness than a non-stimulated half carcass after 14 days.

Lower loss of weight while chilling

Carcasses typically lose weight when hung in the chilling room. The HVES technology:

- makes it possible to use fast and ultra fast chilling methods,

- slowing the drip rate (the meat has sponge consistency) which results in gains of 1-1.5% of carcass weight.

Better brightness in colour by 18-22%

HVES allows better bleeding and deeper oxygen penetration into meat tissue.

Improved consistency

The stimulated muscle has a desired looser and „spongier” consistency in comparison with non-stimulated meat.

Easier boning

The muscle contraction during stimulation results in weaker adhesion and less meat sticking to the bone after boning, providing higher processing efficiency.

Hot boning

Thanks to HVES the hot boning is possible, allowing for faster processing and higher yields, allowing for greater savings.

Increased water absorption

HVES-stimulated beef can be used for cured meat without using phosphates.

Shorter chilling process

Due to changed consistency the meat gets chilled faster, reducing energy costs.

Allows for hot vacuum packing, extending shelf life up to 60 days

The rapid pH decrease from HVES stimulation reduces pathogenic micro flora growth. This is especially important for processing plants which use hot boning to produce small cooking portions of meat that are vacuum packed and then cooled quickly.

Defrosting lower weight loss

The stimulated meat loses less of its weight while defrosting/thawing.

See greater profits

- Additional carcass weight of 1% (scientists point up to 1,5%).

- Processing 100 cows/day = 250 kg more meat to sell each day.

- This translates to 5 500 kg more each month!

See the difference

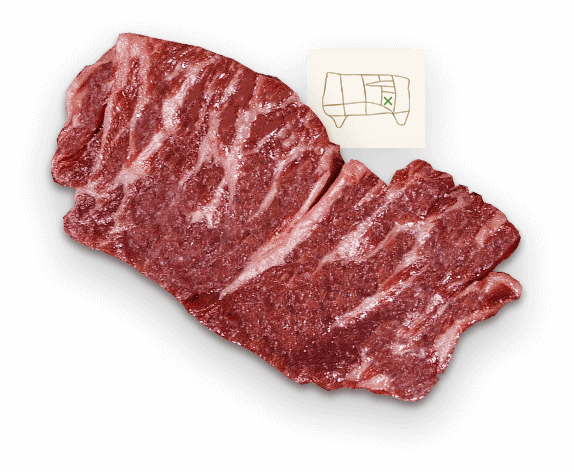

Comparison of meat colour and consistency between stimulated

and non-stimulated half carcasses of the same cow:

Meat from stimulated half carcass

Meat from non-stimulated half carcass

Colour

A big difference in colour between stimulated and non-stimulated meat can be seen with the naked eye in just six hours. This advantage for stimulated meat covers all breeds, although is less visible in young bulls.

Consistency

The muscle is loose and spongier – highly desirable – compared to non-stimulated.